Spaghetti diagram lean planet obeya exchanges colored between each square different

Table of Contents

Table of Contents

Are you struggling with understanding how efficient your processes are? Do you know how to identify the inefficient steps in a process flow? Drawing a spaghetti diagram might be the solution you need!

The process of drawing a spaghetti diagram can be daunting, especially for those who have never done it before. The very act of identifying inefficiencies in a process and visualizing them can feel overwhelming. However, with the right methodology and tools in place, drawing a spaghetti diagram can be simplified and even fun!

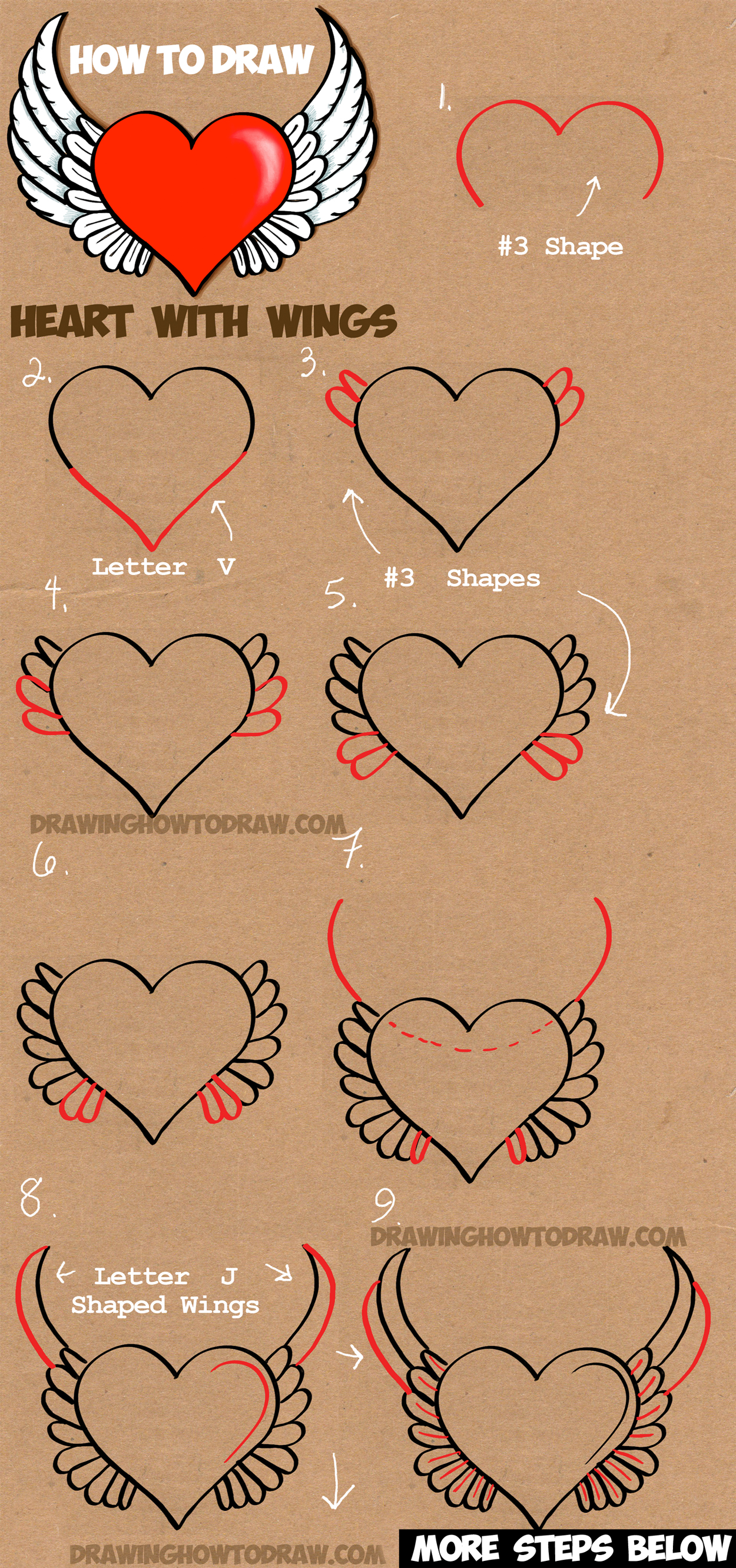

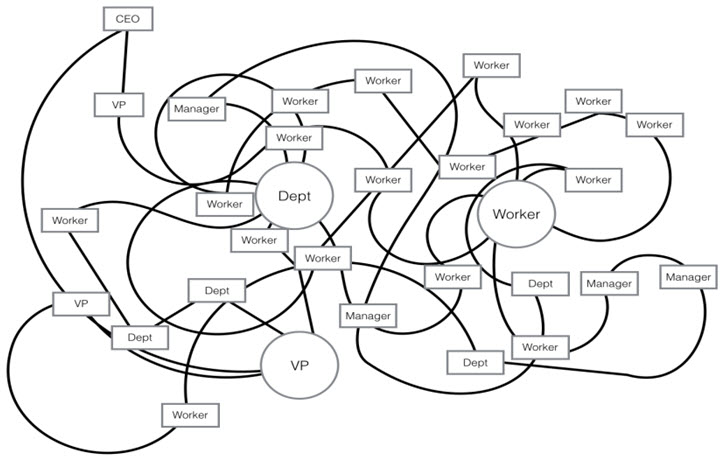

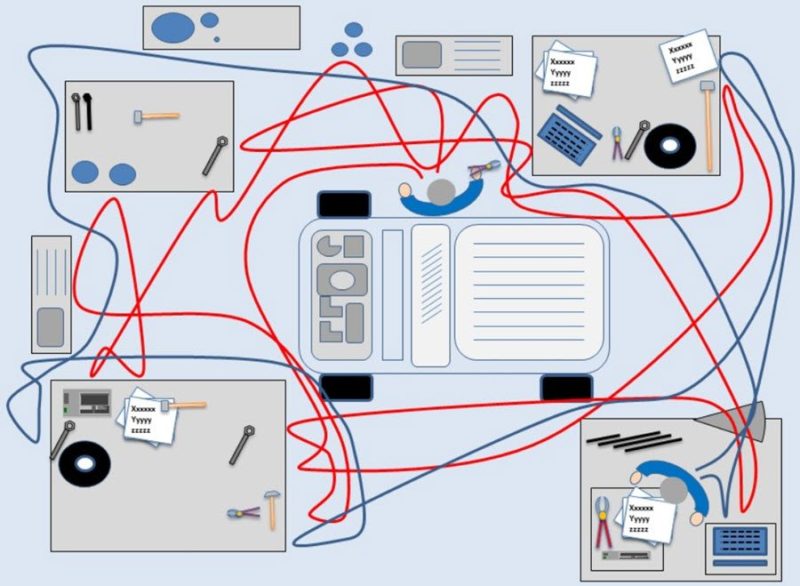

The spaghetti diagram is a tool used to highlight and visualize the flow of materials or people within a process. It can be used to understand how something is moving through the process and identify any issues or inefficiencies. The name “spaghetti” comes from the way the lines can resemble cooked spaghetti noodles when drawn out.

Here are the main points to consider when creating a spaghetti diagram:

Target of a spaghetti diagram

A spaghetti diagram aims to highlight inefficiencies in a process and identify areas for improvement. It can help businesses reduce waste, improve process flow, and ultimately improve their bottom line.

During a spaghetti diagram creation process, team members physically follow the path of the process and mark down their findings on a diagram. This creates a visual representation of the process with the aim of identifying inefficiencies and possible improvements.

Creating a spaghetti diagram may seem confusing at first, so let’s take a moment to walk through my experience with using this tool.

My Experience with Drawing a Spaghetti Diagram

In my experience as a process improvement consultant, creating a spaghetti diagram was crucial in understanding the flow of materials while helping a client improve their supply chain.

First, I gathered the team responsible for operating the process we wanted to improve. Together, we physically walked through the process and marked down all the steps involved. We used different symbols and colors to differentiate the types of movements being made within the process, such as walking, transporting materials, or waiting. Finally, we transferred all our findings to a visual representation of the process.

With the spaghetti diagram complete, our team was able to easily identify several bottlenecks in the process that we then addressed. The end result was an improved process that reduced lead time and waste.

Step-by-Step Process to Draw a Spaghetti Diagram

The following steps outline the process for creating a spaghetti diagram:

Step 1: Identify the Process to Evaluate

Identify the process or area that needs improvement. Gather everyone involved in the process, including both managers and operators, to create a more comprehensive diagram.

Step 2: Map the Current Process

Observe the current process to identify any movements or backtracking in the process flow. Use different symbols to record different types of movement, including walking, waiting or transportation.

Step 3: Transfer Data to a Spaghetti Diagram

Transfer the data collected during Step 2 to a visual representation, the spaghetti diagram. Use a diagramming software, whiteboard, or even a pen and paper to create the visual.

Step 4: Analyze the Spaghetti Diagram

Take a moment to analyze the spaghetti diagram to identify any areas of inefficiency or improvement. Use it as a tool for possible implementation of developed improvement methodology.

Question and Answer

Do I need any special tools or software to create a spaghetti diagram?

No. All you need is a surface to draw or create the visual representation of the diagram with different colored pens or stickers for different types of movement, such as walking or transportation.

Who should be involved in creating a spaghetti diagram?

All team members and management involved in the process being analyzed should be part of the process. The goal is to create a comprehensive diagram that captures every angle of the process being analyzed.

What types of processes or businesses would benefit from spaghetti diagrams?

Any process flow in any industry can benefit from spaghetti diagrams. It can be particularly beneficial for manufacturing and supply-chain businesses, where supply and demand need to be synchronized on regular intervals.

How frequently should a spaghetti diagram be updated?

It is recommended to review and update a spaghetti diagram at least once for every quarter to maintain efficiency and improve the process flow.

Conclusion of How to Draw a Spaghetti Diagram

The spaghetti diagram is a tool that can be used to identify inefficiencies within a process and help businesses reduce waste, improve process flow, and ultimately improve their bottom line. By following the steps outlined in this article and involving the right team members, anyone can successfully create a spaghetti diagram and analyze the data for a more efficient process.

Gallery

An Obeya To Build And Industrialize Our IT Delivery - Planet Lean

Photo Credit by: bing.com / spaghetti diagram lean planet obeya exchanges colored between each square different

How To Create A Spaghetti Diagram Used Within Lean - Latest Quality

Photo Credit by: bing.com / lean

Spaghetti Diagramm - Fromm Engineering

Photo Credit by: bing.com / diagramm fromm

How To Create A Spaghetti Diagram Used Within Lean - Latest Quality

Photo Credit by: bing.com / lean

Was Ist Ein Spaghetti-Diagramm? - VisTABLE® Software

Photo Credit by: bing.com / diagramm diagrams vistable diagramme darstellung